Where is the difference between the aluminum PCB board and the FR4 PCB board?

- Share

- publisher

- PCBQuick

- Issue Time

- Nov 27,2017

Summary

Where is the difference between the aluminum PCB board and the FR4 PCB board?

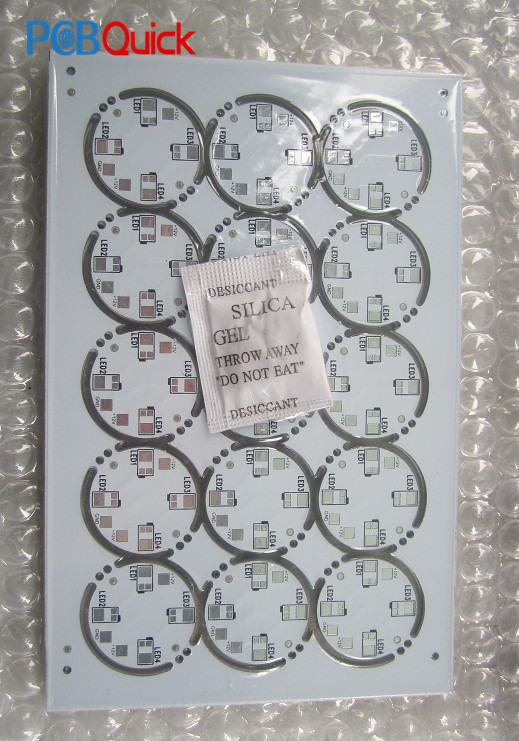

Aluminum Base PCB Board VS FR4 material PCB Board

Aluminum Base PCB Board and FR-4 material PCB board due to the substrate of different heat dissipation, resulting in different circuit board operating temperature rise.

Performance: Conductive lines (copper lines) and fuse currents on different substrate materials are compared.

Due to the high heat dissipation of the metal core circuit board, the fuse current is significantly improved, which shows the high heat dissipation characteristics of the aluminum circuit board from another perspective. Aluminum-based circuit board heat dissipation and its insulation thickness, thermal conductivity. The thinner the insulation, the higher the thermal conductivity of the aluminum-based circuit board (but the lower the voltage resistance).

Machinability:

Aluminum-based circuit boards with high mechanical strength and toughness, this point is better than the FR-4 circuit board. For this reason, a large-area printed circuit board can be manufactured on an aluminum-based circuit board, and heavy-weight components can be mounted on such a substrate.

Electromagnetic wave shielding:

In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum-based circuit board can act as shielding plate, play the role of shielding electromagnetic waves.

Thermal expansion coefficient:

As the general FR-4 materials have thermal expansion problems, especially in the thickness direction of the plate thermal expansion, metallization holes, the quality of the affected line.

This is mainly due to the differences in the thermal expansion coefficients of the slab in the thickness direction of the raw material:

The thermal expansion coefficient of copper is 17 × 10 6 cm / cm • ° C,

FR-4 board substrate is 110 × 106cm / cm • ℃,

The difference between the two is easy to produce: the difference between the expansion of the heated substrate, so that the copper lines and metal-induced fracture damage, affecting product reliability.

The thermal expansion coefficient of the aluminum substrate is 50 × 10 6 cm / cm • ° C, which is smaller than that of a typical FR-4 plate and closer to the thermal expansion coefficient of the copper foil. This will help ensure the quality and reliability of printed circuit boards.

Applicable to different circuits, different applications, FR-4 board for general circuit design and general electronic products. Aluminum-based materials for the LED lighting industry and high-power thermal products.

Maybe it’s helpful to you:

Web link