5 Common Mistakes in Assembling Printed Circuit Boards

- Share

- Issue Time

- Aug 5,2021

Summary

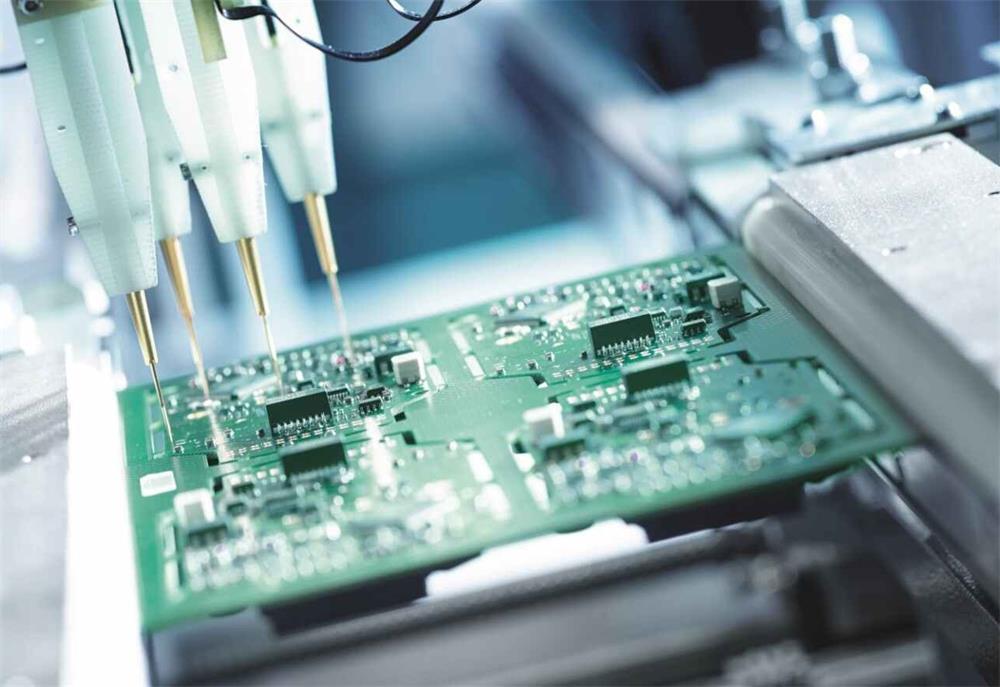

If the printed circuit board has some wrong operations during assembly, its final performance cannot be guaranteed. This article will specifically introduce five common mistakes in assembling printed circuit boards.

If there are some failures in the PCB assembly process, such as defects in the technical design, or errors in the operation, the final product will have defects. Therefore, it’s necessary to learn about the following five common mistakes in assembling printed circuit boards.

Ceramic chip is overstressed

When the stress on the ceramic chip capacitor is excessive, it will cause excessive bending of the PCB during assembly. Because ceramic chip capacitors are designed to withstand a specific load, when the load generated by the PCB exceeds its maximum capacity, stress will be generated on the ceramic chip capacitor, which will cause the PCB to bend. It is very important to use the same or similar load-level ceramic chip capacitors in the design stage to ensure that the capacitors will not be stressed to ensure the final performance of the PCB.

No obvious polarity

Assembling a PCB requires many different components, such as batteries and diodes, which are characterized by polarity. Marking the polarity of each individual component is very important for the assembly staff to distinguish between anode and cathode.

If the polarity is not clearly marked or the marking is wrong, it is very likely that the wrong polarity will be connected to the wrong terminal during the PCB assembly process. A short circuit in the PCB is usually caused by the wrong connection between the polarity and the terminals, and it may even cause the circuit to explode or cause some components on the PCB to be completely destroyed.

Corroded copper coating

The high conductivity of copper makes it an ideal metal for electrical and electronic PCBs. However, as a metal, copper is also very susceptible to corrosion, and corrosion will occur if the copper layer is exposed to the environment. This is why the copper used in PCB assembly is usually coated with other materials, such as plastic, to prevent corrosion.

But sometimes in the process of trimming the printed circuit board, the copper coating is also trimmed, causing the lower part to be exposed to the environment, which increases the possibility of corroding the PCB. This error can be easily avoided by ensuring that the space between the edge of the board and the edge of the copper (also called internal gap or copper-to-edge gap) adheres to specific quality standards.

An error occurred during the electroplating deposition process

An important part of the PCB assembly process is the electroplating process. This process is mainly used to drill holes on a circuit board, through which power can be transmitted from one end of the circuit board to the other end. Once the hole is drilled, a thin layer of electroless copper is added to the board and along the whole wall for etching the printed circuit board. Errors in the deposition process may lead to copper-plated holes, thereby preventing current from passing through the holes and causing the entire PCB to fail.

Component misalignment

Each component on the printed circuit board has a specific landing point. Sometimes, during the soldering process, the component is displaced from its target position by attaching itself to the molten solder. Misaligned components may disrupt the normal current through the circuit board, causing the entire PCB to malfunction.

If we can avoid these wrong operations in the process of assembling the PCB, we can reduce the number of subsequent failures of the PCB. If you want to know more about PCB-related information after reading the above, you can get professional solutions by contacting us.

As a professional PCB product manufacturer, we have won praise and trust from many customers with our high-quality products and services. We have an experienced production team and staff, put the needs of customers first, and strictly control the quality of every link in the production process. We will also provide thoughtful one-stop service and effective solution technology according to the diverse needs of customers. If you are interested in our printed circuit boards, please contact us immediately!